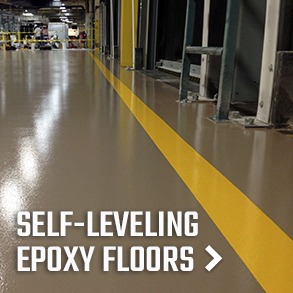

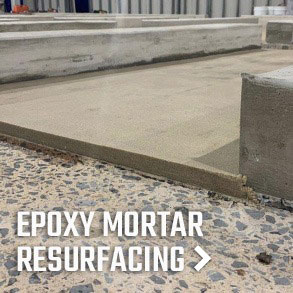

Industrial Floor Coating

At PennCoat, we understand that each facility has different needs when it comes to making your concrete floor attractive, functional and safe. From epoxy floor coatings and resurfacing, to urethane floor systems and non-slip flooring options, PennCoat has you covered. We’re a resource that facility managers can depend on to work quickly, safely, and get the job done right.

Learn more about how PennCoat can help with your commercial/industrial floor coating needs below, and contact us today with any questions you might have. Our team is standing by and ready to help.

If you’re looking for more than just a new floor, consider working with true professionals who will help keep your facility safe, clean and looking sharp. Contact us today for more information. We look forward to hearing from you!